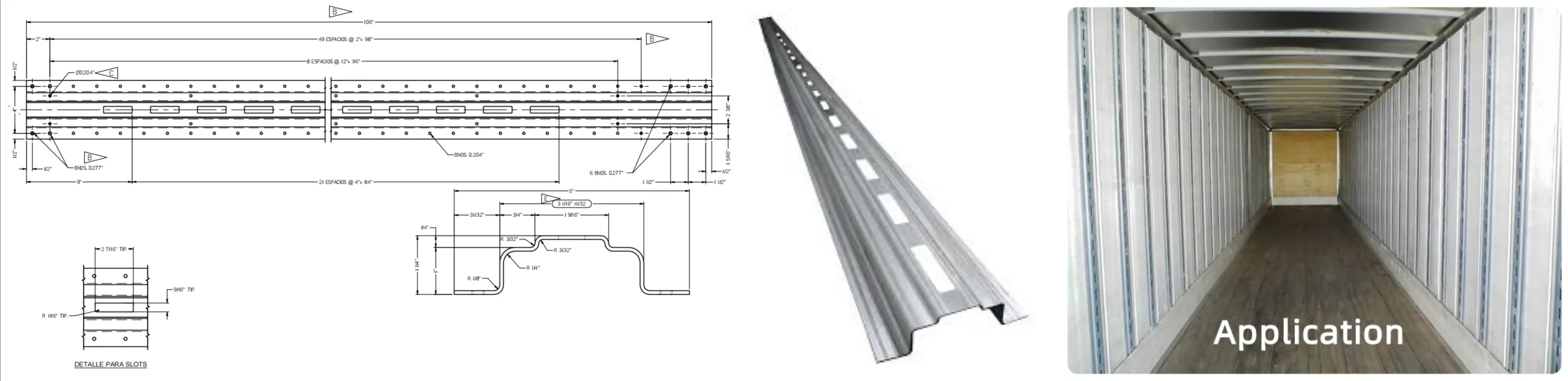

This production line is specially designed for manufacturing logistic post profiles used inside truck and trailer bodies, widely applied in the logistics and transportation industry in markets such as Mexico, the United States, and other regions across the Americas. These profiles are commonly found in dry van trailers, semi-trailers, and refrigerated trucks, serving as critical components for cargo partitioning, reinforcement, and securement systems.

Ø Standard thickness: Gauge 14

Ø Standard lengths: 2.44 m, 2.80 m, and 3.05 m

The logistic post is a roll-formed steel profile with continuous perforations, typically made from galvanized steel strips. The holes are evenly spaced along the center of the profile, allowing for easy installation of horizontal bars, hooks, straps, and other accessories to achieve flexible cargo restraint and interior organization.

Key features include:

Strong structure and high compression resistance;

Standardized hole patterns with uniform spacing, compatible with most mainstream accessories on the market;

This type of profile has become a standardized component for truck interiors in the American market, with stable and high-volume demand.

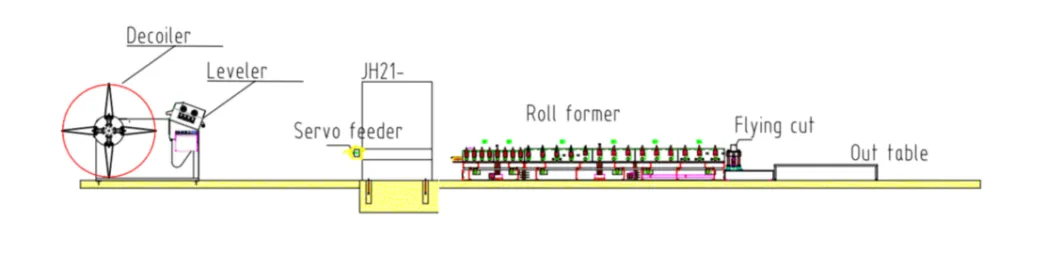

This production line features a modular structure and a clear, efficient production rhythm, well-suited for high-volume, standardized manufacturing. All equipment is industrial-grade and optimized for precision, consistency, and performance, with a maximum line speed of 8m/min. The complete configuration includes:

| Logistic posts roll forming machine | ||

| Profile: | ||

| Item | Additional information | |

| Raw material: | Steel grade 50 galvanized G-60 | 2mm (Gauge14) |

| Yield strength: | ≤350Mpa | |

| The line: | ||

| Speed of the whole line: | 8m/min | |

| Power supply: | 440V 60Hz 3Ph | * Or according to your requirement |

| Decoiler and Leveler with Loading car: | ||

| Decoiler: | Hydraulic | 3kw |

| Capacity of the decoiler: | 3 tons | |

| Leveler: | 7 rollers | 5.5kw |

| Roller diameter: | 80mm | |

| Speed: | 0-20m/min | |

| Capacity of the loading car: | 3 tons | |

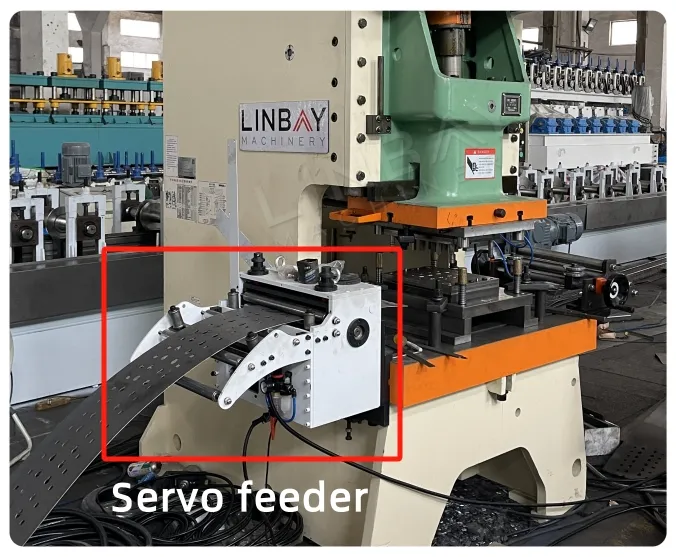

| Servo Feeder: | ||

| Power of the servo motor: | 3kw with reducer | Yaskawa |

| PLC: | Siemens | |

| Touch screen: | MCGS | |

| Feeding roller diameter: | φ100mm | |

| Raw material of rollers: | 40Cr | HRC55°-58°, chromed |

| Precision of feeding: | ≤±0.1 mm (within 200 mm) | ≤±0.2 mm (within 500 mm) |

| Air supply pressure: | 0.7Mpa | |

| Flow rate: | 0.5m³/min | |

| Feeding speed: | 0-20m/min, adjustable | |

| Punch Press: | ||

| Model: | JH21-125T | Yangli brand |

| Work method: | Pneumatic type | |

| Punch speed: | 80times/min | |

| Nominal force: | 125tons | |

| Motor power: | 18.5kw | Siemens brand |

| Air supply pressure: | 6kg/cm² | |

| Material of the upper and lower die plates: | A3 | |

| Raw material of the punch: | SKD-11 | HRC>62° |

| Number of dies: | 1 set | |

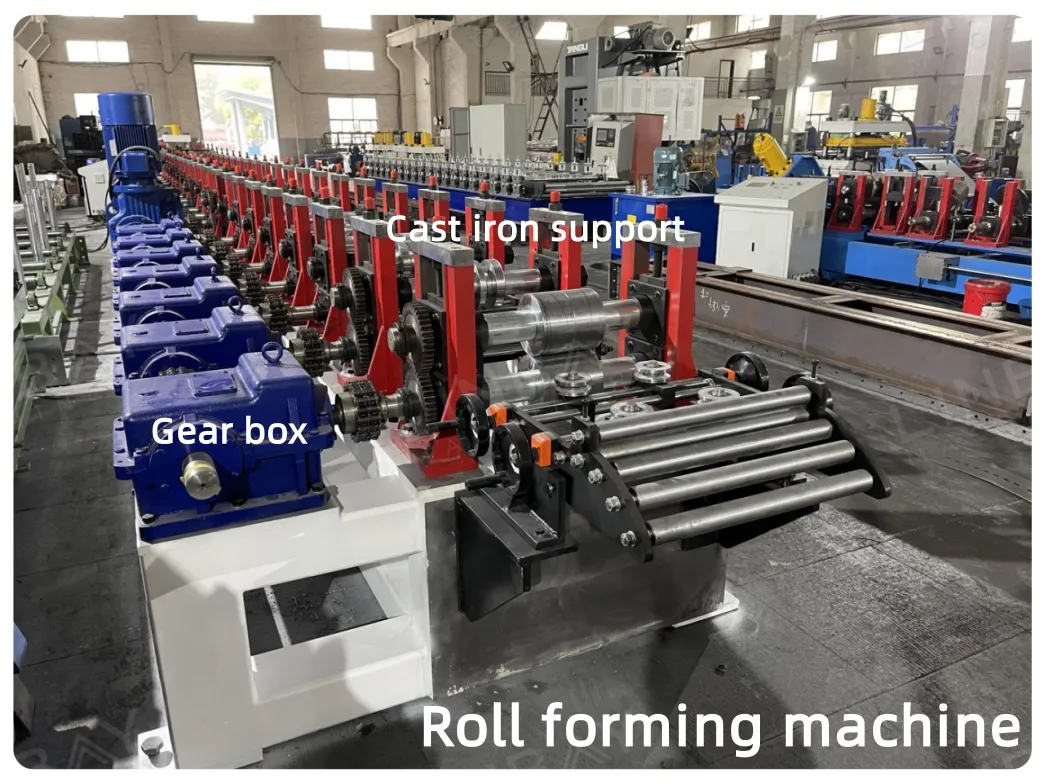

| Roll forming machine: | ||

| Speed: | 8m/min | |

| Structure: | Cast iron support | |

| Transmission system: | Gear box | |

| Motor power: | 15kw | 5 year warranty |

| Forming station: | 18 stations | |

| Shaft material: | 40Cr | |

| Roller material: | Cr12 | 5 year warranty, HRC58-62° |

| Shaft material: | φ80 mm | 5 year warranty |

| Bearing brand: | HRB | 2 year warranty |

| Flying hydraulic cut: | ||

| Work method: | Hydraulic | Before cutting, there is a straightener to ensure the profile's shape |

| Speed: | 8m/min | Same as the roll forming part |

| Width of scrap: | 8-15mm | According to its design |

| Servo motor power: | 3kw | Yaskawa brand |

| Raw material of cutting blade: | SKD11 | HRC>62° |

| Number of blades: | 1 set | |

| Blade lisfspan: | 2 million cuts | |

| Encoder brand: | Omron 1000P | |

| Hydraulic motor power: | 7.5kw | Provided by the hydraulic station |

| Length tolerance: | ≤+/- 0.5mm | |

| Out table: | ||

| Work method: | Receive and load the formed profiles | No power |

| Number: | 2 pieces | * Or according to your requirement |

| Dimension: | 2m(L)*1.3m(W)*0.795m(H) | |

| Hydraulic station: | ||

| Power: | 7.5kw | |

| Brand: | Wuxi Wansheng | Air cooling |

| Solenoid: | Beijing Huade | Chinese famous brand |

| Hydraulic valve: | Beijing Huade | Chinese famous brand |

| Hydraulic oil: | N32/N46 | |

| PLC Control: | ||

| Inverter: | Yaskawa brand | |

| PLC: | Siemens brand | |

| Type of operation: | Manual/automatic operation types | |

| HMI: | MCGS brand | |

| Contactors: | Schneider brand | |

| Developers: | Omron brand | |

| Intermediate relays: | Omron brand | |

| Language: | Chinese-Spanish | |

| Other information: | ||

| Color: | Red and blue | * Or according to your requirement |

| Delivery: | 120 Days | |

| Container: | 2*40GP | |

| Manual: | Chinese-Spanish | |

【1】Decoiler & Leveler (with Loading Car)

The decoiler enables automatic loading and uncoiling of steel coils, assisted by a hydraulic loading car for efficient and safe positioning. The leveling unit uses a multi-roller structure combined with tension control to ensure the flatness and tension consistency of the material before it enters the next stages — which is critical for forming precision.

A pressing arm is mounted on the decoiler to prevent coil spring-out, ensuring safe operation.

【2】Servo Feeder + Punch Press

The servo feeding system supports multi-stage step control and allows pre-programmed punching distances and patterns based on the profile drawing. It offers high precision and fast response. The high-speed press delivers stable punching force with clean, accurate holes, effectively protecting die lifespan.

The punching press is paired with an independent control cabinet, and the screen interface language can be customized according to the client's needs.

【3】Roll Forming Machine

The forming unit adopts a high-strength cast iron frame to ensure rigidity and deformation resistance during high-speed forming. It uses gearbox transmission, which is more efficient, synchronized, and quieter than traditional chain drives.

Forming rollers are customized based on product design and made of quenched alloy steel, ensuring long-lasting precision without deformation.

The forming machine is also paired with a dedicated control cabinet with a customizable screen language.

【4】Hydraulic Tracking Cutting System

This system uses hydraulic-driven cutting combined with a tracking mechanism, allowing the cutting head to move synchronously with the material. This enables non-stop shearing, significantly improving production speed and efficiency.

Blades are specially heat-treated for clean cuts, minimal burrs, and extended maintenance intervals.

【5】Air-Cooled Hydraulic Station

The hydraulic station powers the cutting system and features a built-in air cooling system. This design helps maintain oil temperature during long-term, high-frequency operations, ensuring stable system performance and extending service life.

1. High productivity: Line speed up to 8 meters per minute, ideal for mass production.

2. High automation: Automatic feeding, punching, forming, and cutting help reduce labor costs.

3. Customization available: Full line and tooling customization based on your profile drawings and process requirements.

We provide complete solutions, including line design, on-site installation, remote debugging, and operator training — helping clients achieve rapid production and stable delivery.

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)