Hemming-reinforced shelf deck roll forming machine

1. Produces pallets of different widths by automatically adjusting the lateral displacement.

2. The cassette is used to produce reinforcement ribs; when ribs are not needed, the cassette can be removed.

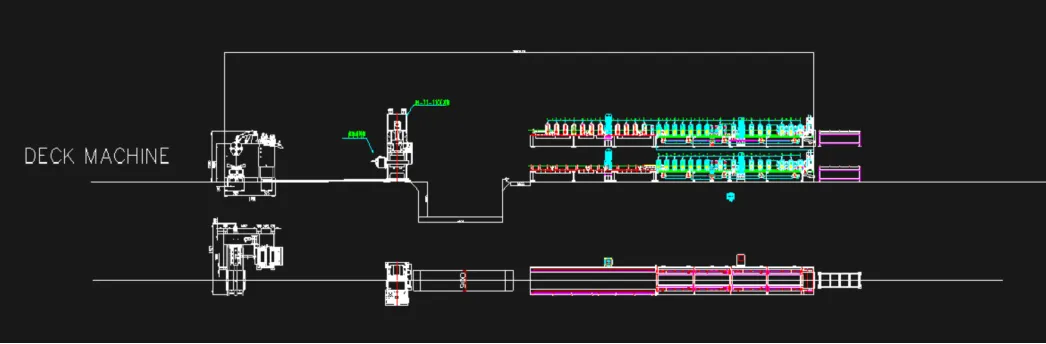

Decoiler and leveler--Punch press--Roll forming machine--Hydraulic cut--Out table

Decoiler and Leveler:

Compared to a separate decoiler and a separate leveler, the integrated decoiler-leveler machine can save space. If independent decoiler and leveler are used, about 3 meters of space is needed between them.

The decoiler is equipped with a pneumatic pressure arm that holds the steel coil to prevent it from unrolling and injuring the worker.

This decoiler is also equipped with a loading car to facilitate the coil loading process.

It is necessary to level the steel before punching to release internal stresses and improve the efficiency of the punching and forming process.

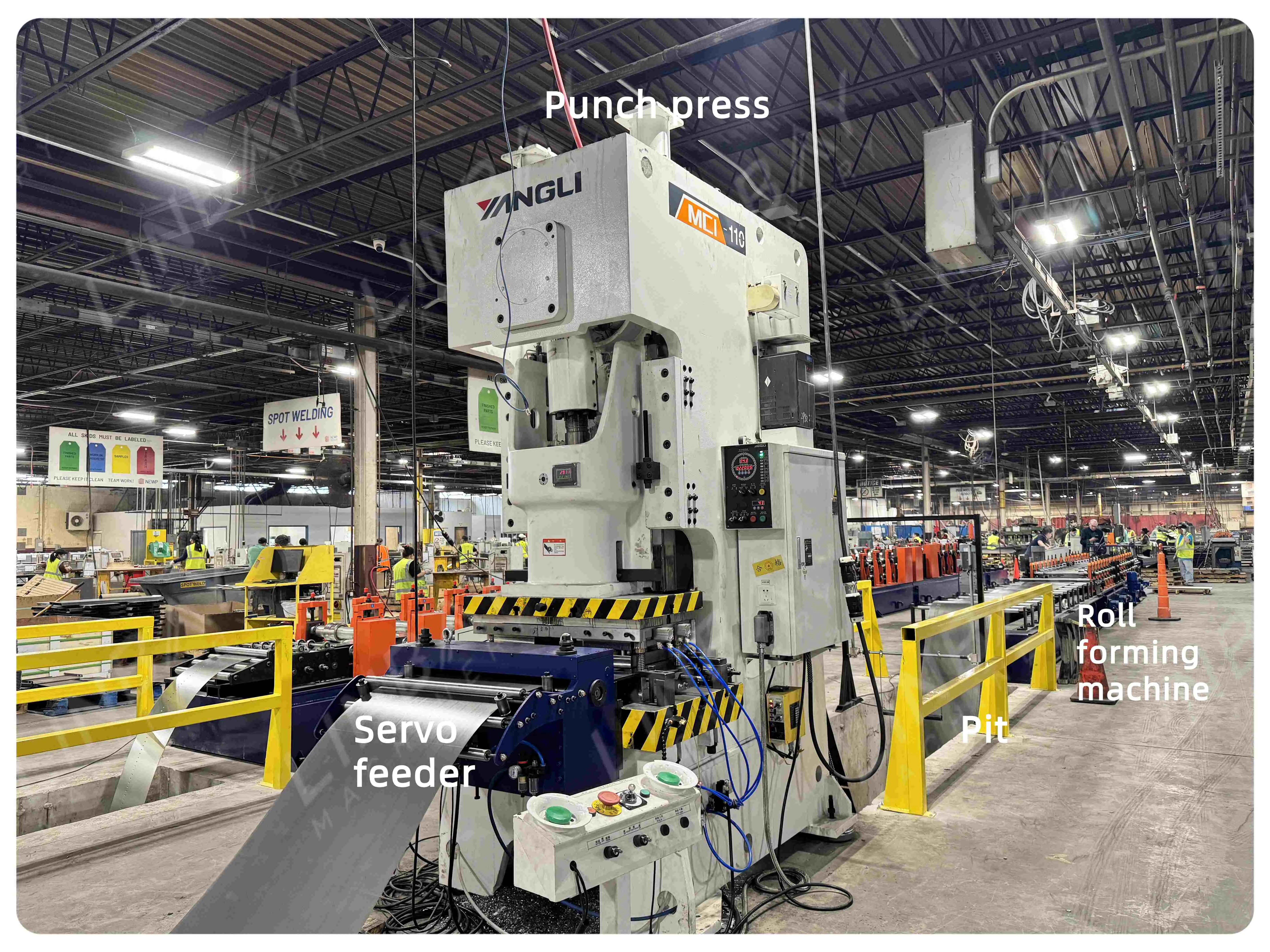

Punching Machine:

We use a 110-ton Yangli brand punching machine. Because the holes needed to be punched in the profiles are dense, using a punching machine can increase the line’s efficiency compared to a hydraulic press. The Yangli brand has after-sales service points in Mexico, so customers don’t worry about post-sale issues.

The punching machine is equipped with a servo feeder, whose advantages are fast feeding speed and high precision, ensuring accurate punching position.

The punching machine is combined with an independent electrical cabinet. We provide each customer with an instruction manual explaining the operation of the electrical cabinet.

Between the press and the forming machine, there are limit sensors to coordinate speeds. When the steel touches the lower limit, indicating that the punching machine speed is too fast, the punching machine stops. When the steel touches the upper limit, indicating that the forming machine speed is too fast, the machine stops.

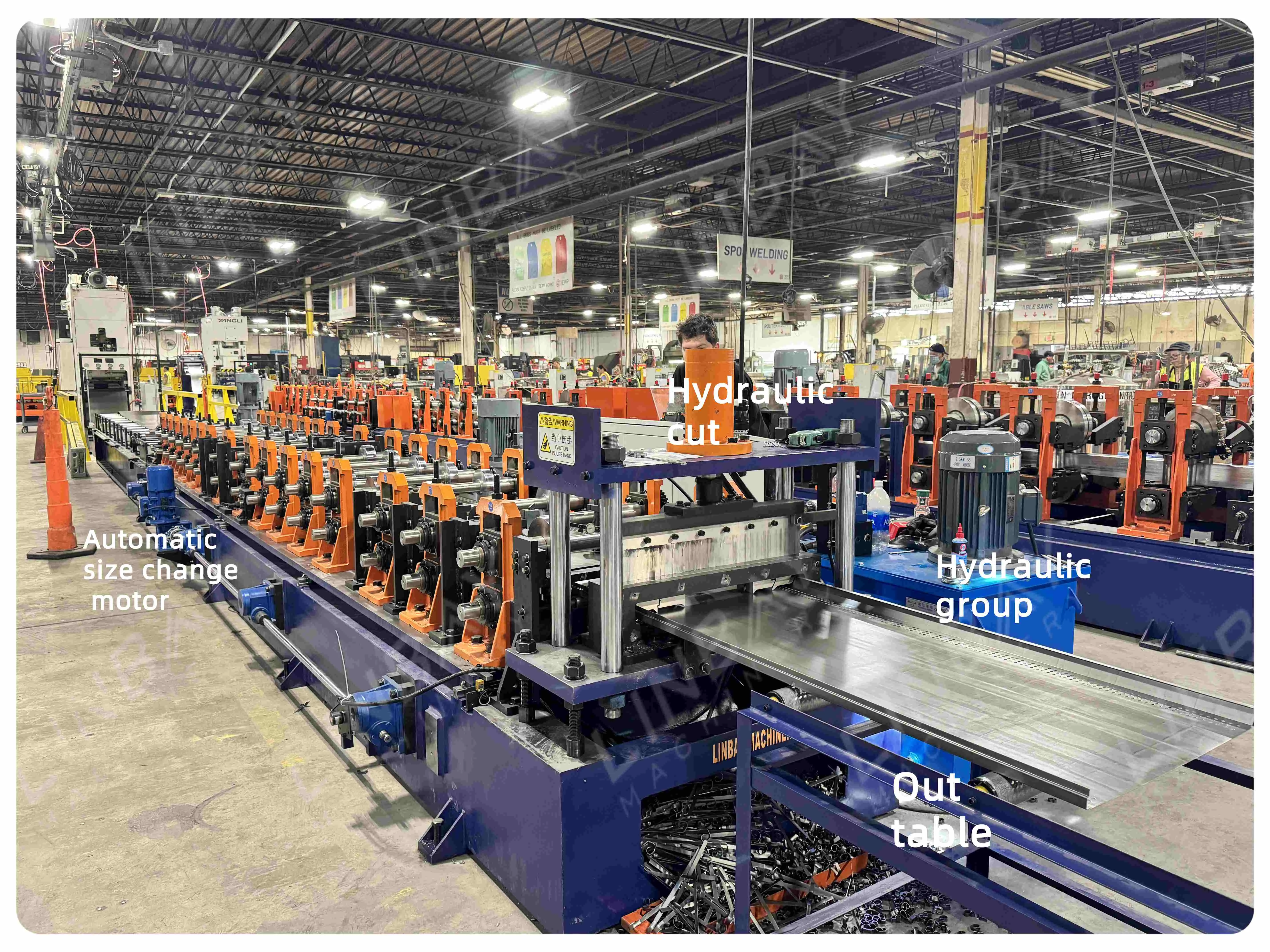

Roll Forming Machine:

The roll forming machine has a cast iron structure and operates with chain transmission. In total, there are 28 forming stations, of which 12 are used to form ribs. This part can be removed when ribs are not needed.

We offer a five-year warranty for the motors and rollers. The rollers and shafts are treated to extend their service life.

Hydraulic Cutting:

We use hydraulic cutting with the machine stopped. It uses a photocell cutting system, which starts cutting when the photocell detects multiple perforations. The cutting produces waste of 8–10 mm. If there is any error in the length of the cut profile, it can be corrected simply by re-entering the data on the control panel. Detailed instructions can be found in the manual.

| Hemming-reinforced shelf deck roll forming machine | ||

| Item | Optional configuration | |

| Raw material: | A1008 and A1011 | Thickness(MM): 0.8mm/Gauge22 |

| Yield strength: | 25-35ksi | |

| Line speed: | 4-5pcs/min | |

| Decoiler and leveler: | Hydraulic | With loading car |

| Decoiler loading capacity: | 5T | |

| Number of leveling rolllers: | 7 rodillos | |

| Diámetro de rodillos de aplanador: | 80mm | |

| Servo motor power: | 3kw with reducer | |

| Punch press: | JH21-110 | Yangli Brand |

| Punch press working method: | Pneumatic | |

| Punch press speed: | 40 times/min | |

| Raw material of upper and lower die: | A3 | |

| Raw material of mold: | SKD-11 | 1 set |

| Roll forming motor power: | 7.5kw*2 | 5 years warranty |

| Width change motor power: | 1.5kw*2 | 5 years warranty |

| Transmission system: | Chain | |

| Cassette type: | Cassette of 12 roll forming stations | Reinforcement forming |

| Roll forming stations: | 16+12 | |

| Machine structutre: | Cast iron support | |

| Shaft material: | 40Cr | |

| Roller material: | Cr12 | 5 years warranty |

| Shaft diameter: | φ60 mm | 5 years warranty |

| Width adjustment: | Transverse automatic | Few seconds |

| Cutting method: | Hydraulic cutting | Stop to cut |

| Hydraulic cut method: | 5.5kw | |

| Width of material loss: | 8-10mm | |

| Blade raw material: | SKD11 | 2 sets |

| Encoder brand: | Omron | |

| Length tolerance: | ≤+/- 0.5mm | |

| Out table length: | 4m | |

| Inverter: | Yaskawa Brand | |

| PLC: | Siemens Brand | |

| HMI: | MCGS Brand | |

| Language: | English | Or spanish |

| Power supply: | 480V 50Hz 3Ph | * Or according to your requirement |

| Color: | Blue and orange | * Or according to your requirement |

| Delivery: | 120 Days | |

| Container: | 2*40GP | |

| Total weight: | 40T | |

| Dimension: | 30m (L)*2.2m (W) | |